File Download

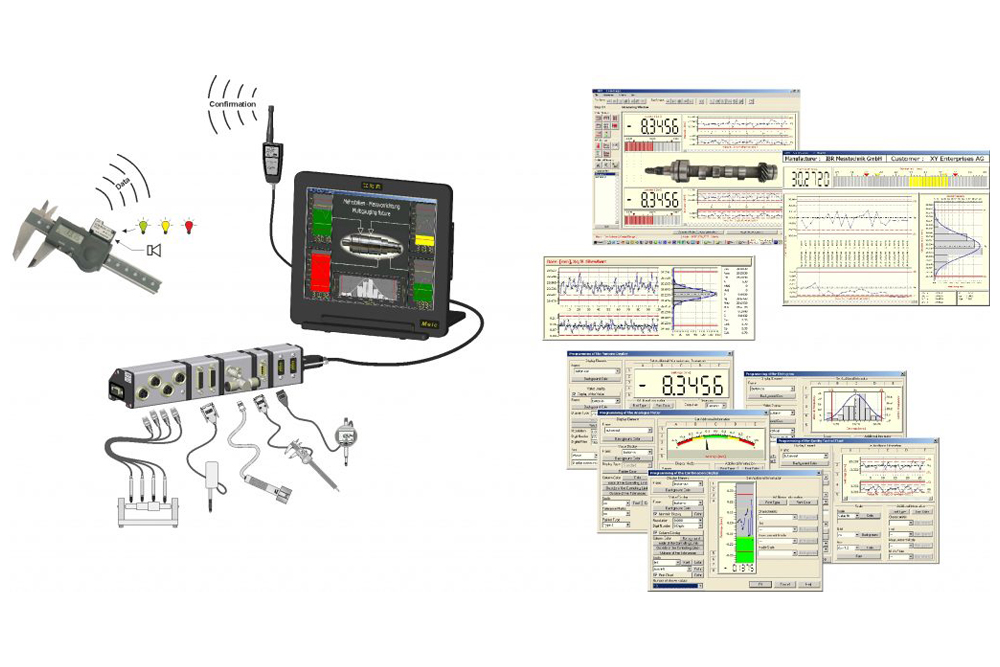

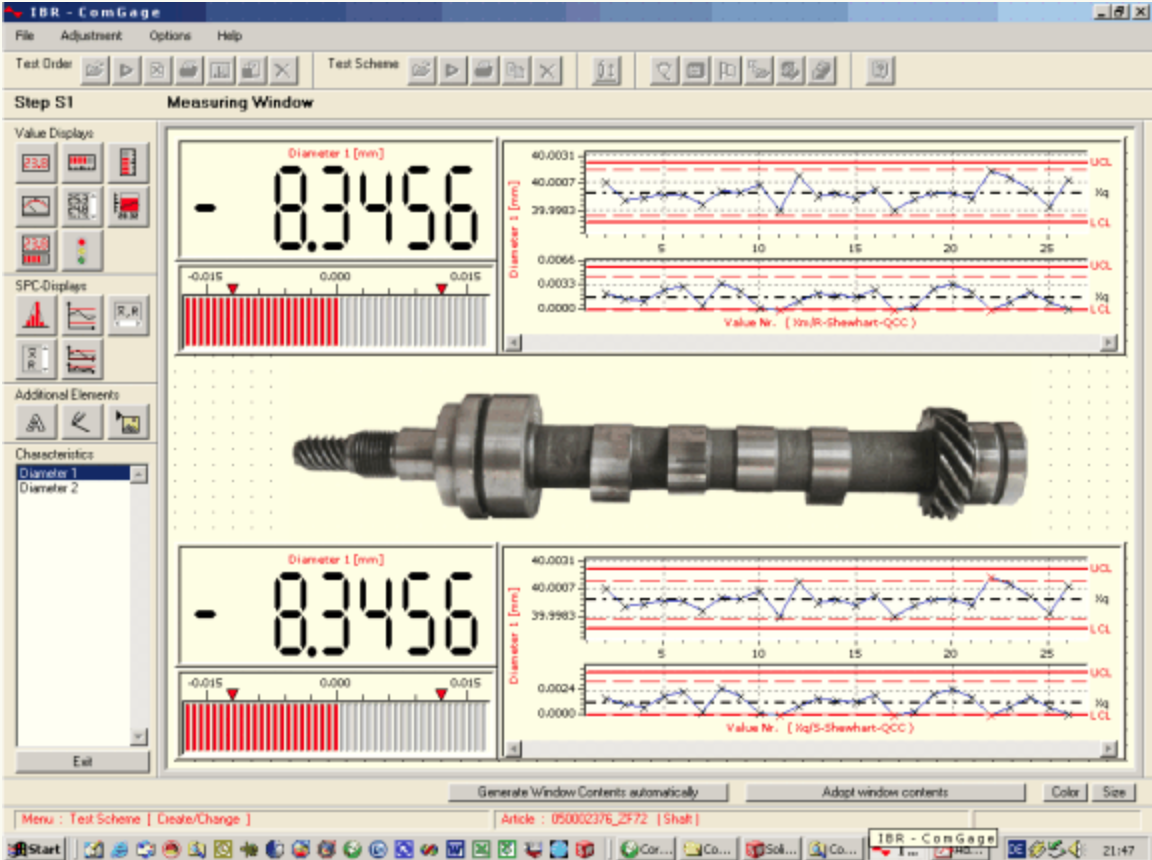

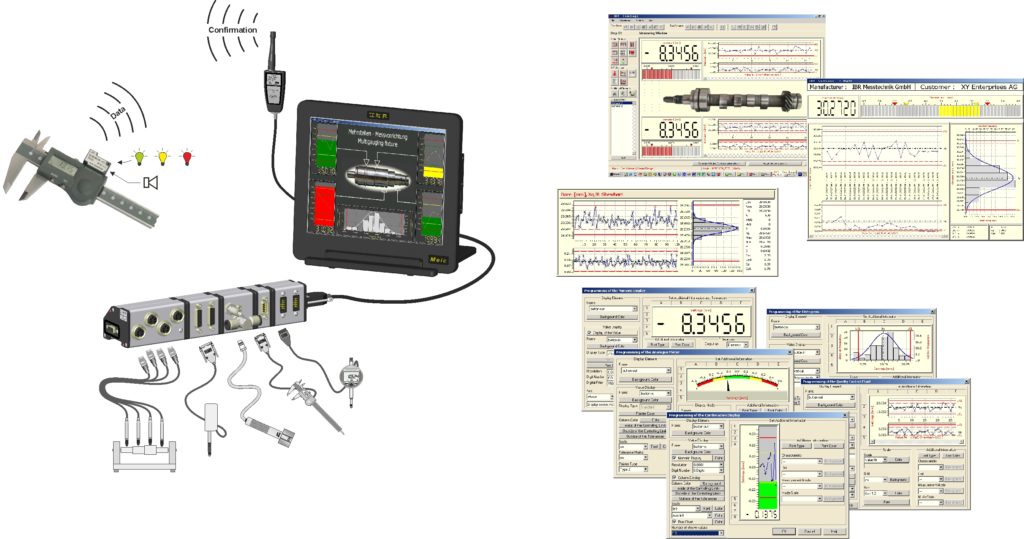

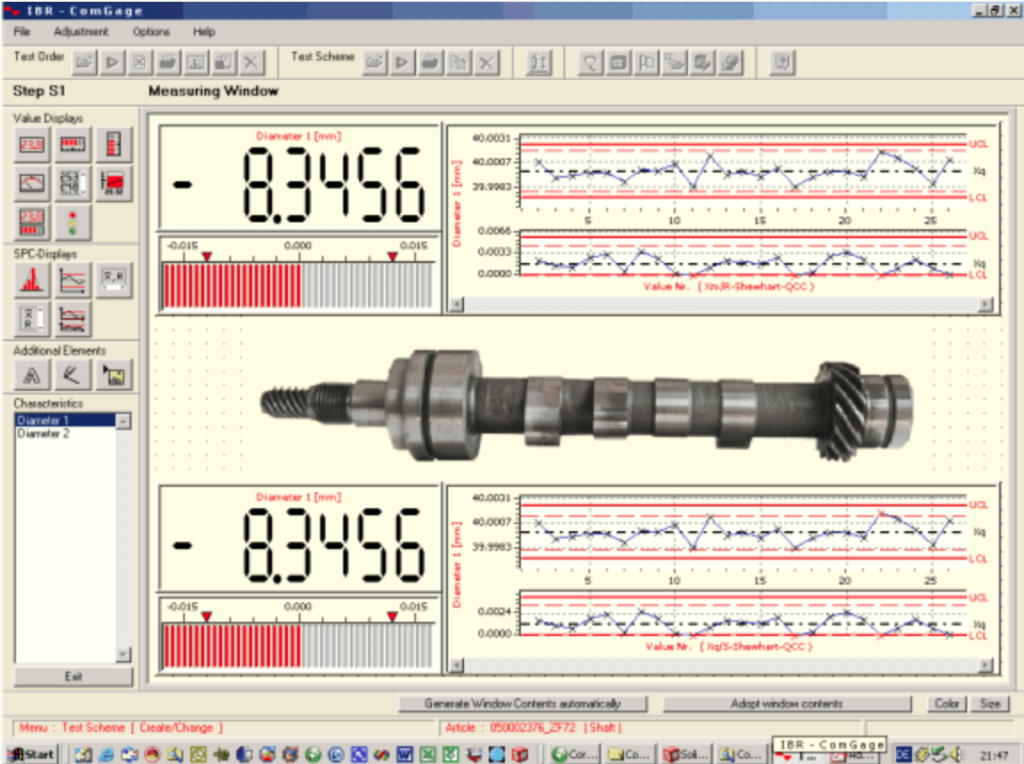

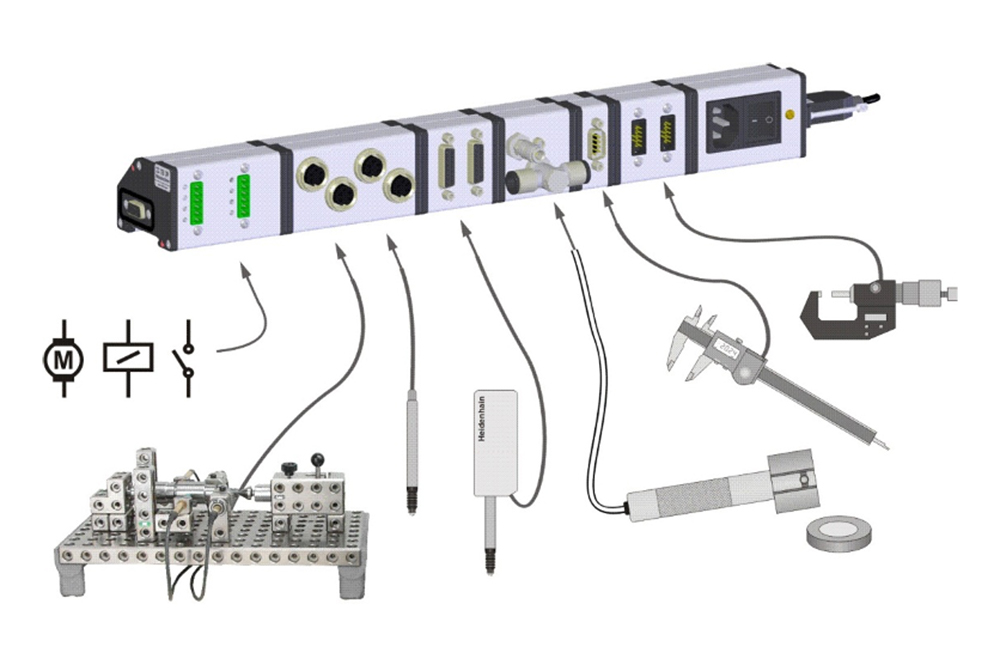

LinkComGage is a software for metrology and statistical process control on manufacturing sites. The software is suitable for simple displaying of measured values up to complex measuring applications with control sequences, as well as for testing of components with several characteristics in small and large series.

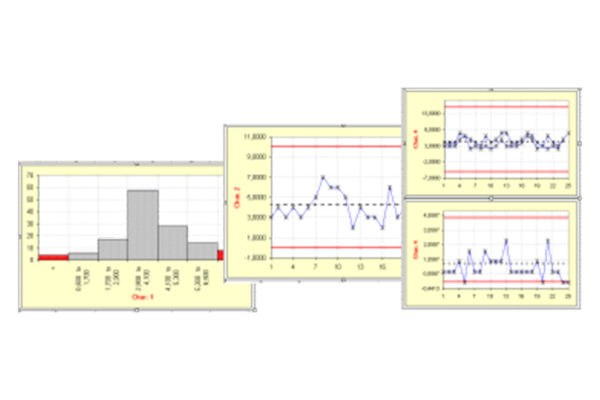

Additionally, the software provides information for statistical process control by means of the included statistical functions.

Key features

- Simple and easy handling – Low cost and modular

- Universally usable for simple hand gauge stations, multi gauging fix- tures and automatic measuring sequences

- Data collection from gauges, interfaces and by keyboard

- Universal mixing of measuring inputs as well as measuring programmes for run-out, roundness, flatness, coaxiality, …

- Graphical surface for creating the display windows

- Simple measuring sequence control – Online SPC – elements

- Control of digital outputs and reading of digital inputs

- Collection of reference information

- Printing of test reports and measured values in table form

- Converter for MS-Excel and QS-Stat – For Windows 95…Win 7 and CE – European and Asiatic languages

A professional metrology software

The software is available in 3 different editions :

ComGage Level 1 is part of the standard scope of delivery for the IBR devices with Windows CE operating system and transforms them into gauges for standard measuring applications

ComGage Level 2 serves for simple and fast solving of measuring applications. An easily surveyed and user friendly surface allows a fast settling in the software. Basic functions for control tasks and for collecting reference information make the program useful for nearly all measuring applications

ComGage Professional is a complete solution for the field of metrology and SPC on manufacturing sited. Extended functions for collecting reference information, the order dependent storing of values, a formula editor for complex control tasks and a user setup assure universal usage. Additional features such as printing of barcodes, sending emails, correction data transfer to CNC machines can be individually added to ComGage Professional.

Related products

IBR ISi accessories

The IBR Messtechnik ISi accessories for the IBR IMS Measuring probes enable highly customisable and…

IBR SD1

The IBR Messtechnik SD1 sensor display unit was especially developed for industrial use. The robust…

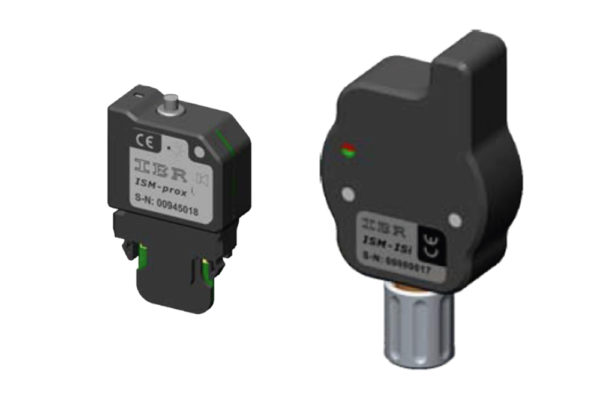

IBR ISM Wireless

The ISM radio module series from IBR Messtechnik allows wireless transmission of measured values from…

IBR IBREXDLL Software

The IBREXDLL software allows the reading of data from all IBR interfaces and measuring instruments…

IBR CD70 Computer Display (7.0″)

The computer display CD70 is a compact and powerful display unit for measuring applications, which…

IBR CD43 Computer Display (4.3″)

CD43 a computer display for industrial use The computer display CD43 is a small and…

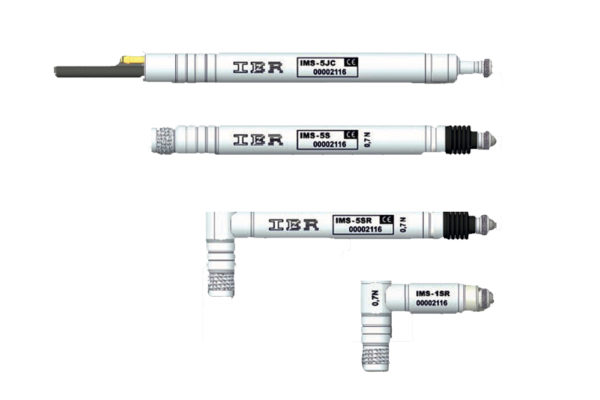

IBR IMS Measuring probes

The IMS measuring probes from IBR Messtechnik are a new generation of inductive measuring probes…

IBR MEIC Measuring Computer (17″)

The measuring computer Meic is a robust and universal industrial computer for manual and automatic…

IBR MECC Compact Measuring Computer (8.0″)

The compact measuring computer Mecc is a robust and universal industrial computer for manual and…

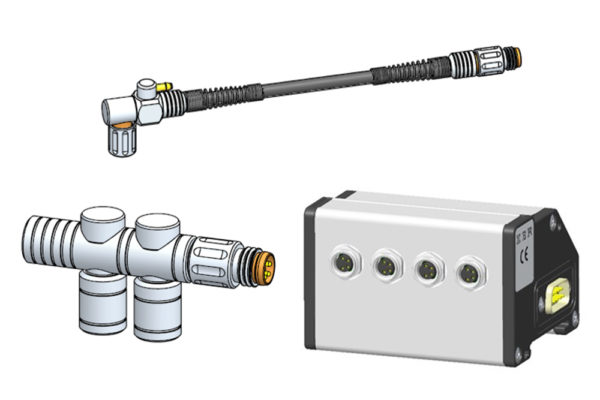

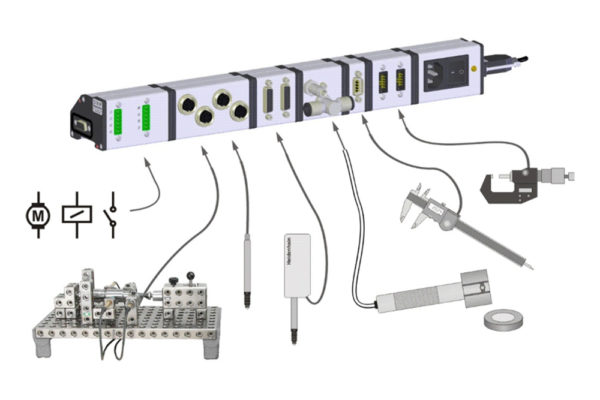

IBR IMBus Modular

The IBR Messtechnik Measuring Bus [IMBus] is a technology step in metrology and interface technology….

IBR C200 Column Gauge

The Column gauge C200 is an electronic gauge for connecting 1 – 8 inductive and…

IBR B200 Digital Gauge

The digital gauge B200 is an electronic gauge for connecting 1 – 8 inductive and…