File Download

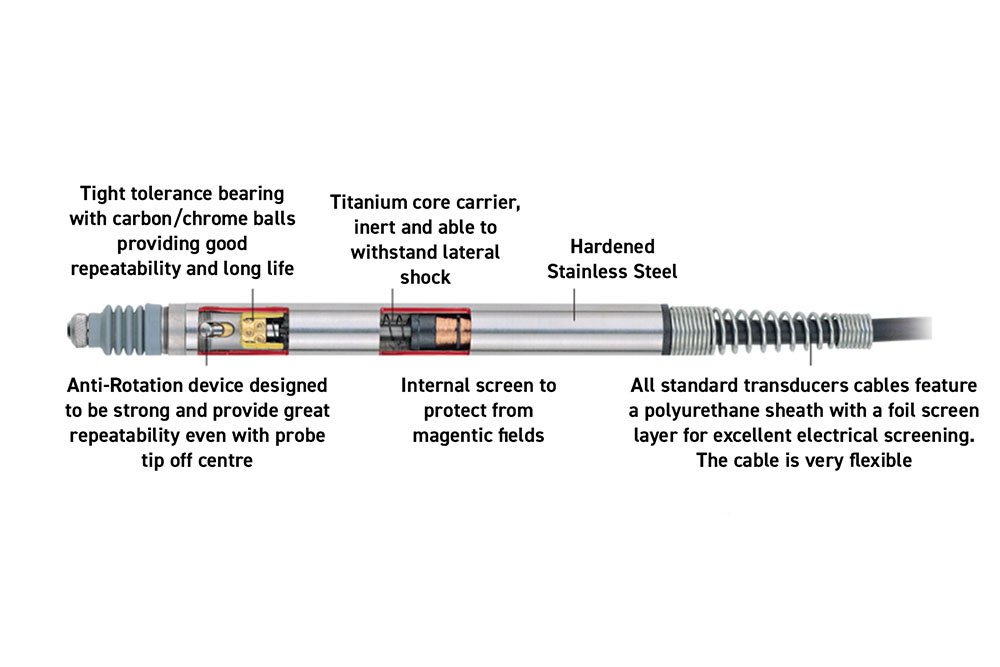

LinkSolartron Metrology contact gauging probes provide the gauge builder with the most cost-effective solution for a range of dimensional precision measurement and positioning applications. Contact gauge probes often provide the most cost effective solution for a wide range of measuring and positioning applications. These have excellent sideload capabilities and can last over 100 million cycles.

Key features

- Spring, Pneumatic, or Vacuum actuation

- ±1, ±1.5, ±2.5, ±5 & ±10 mm measuring ranges

- Accuracy as low as 1 μm

- Up to 0.05 μm measurement repeatability

- Range of contact sensor tips available

Contact gauge probes often provide the most cost effective solution for a wide range of measuring and positioning applications

In a conventional pencil probe the tip is pushed out using an internal spring. When installed in a fixture it is frequently required to design a mechanism to bring the probe into contact with the part being measured.

A pneumatic probe (either pneumatic push or vacuum retract) allows the number of parts in the fixture to be reduced resulting in improved reliability and reduced fixture cost. It also allows for fast automatic loading of the part into the gauge as the probe tip can be in the fully ‘retract position’ when this is occurring. Probes such as the AX/5/1 have a mechanical movement of 10 mm with a calibrated range of ±1 mm at the beginning of the movement.

With conventional pneumatic transducers, the air pressure is contained within the gaiter. The Jet range pneumatic transducers are designed so that the gaiter is not pressurised. This has the advantage that gaiter damage will not affect operation resulting in less downtime and reduced cost of ownership.