File Download

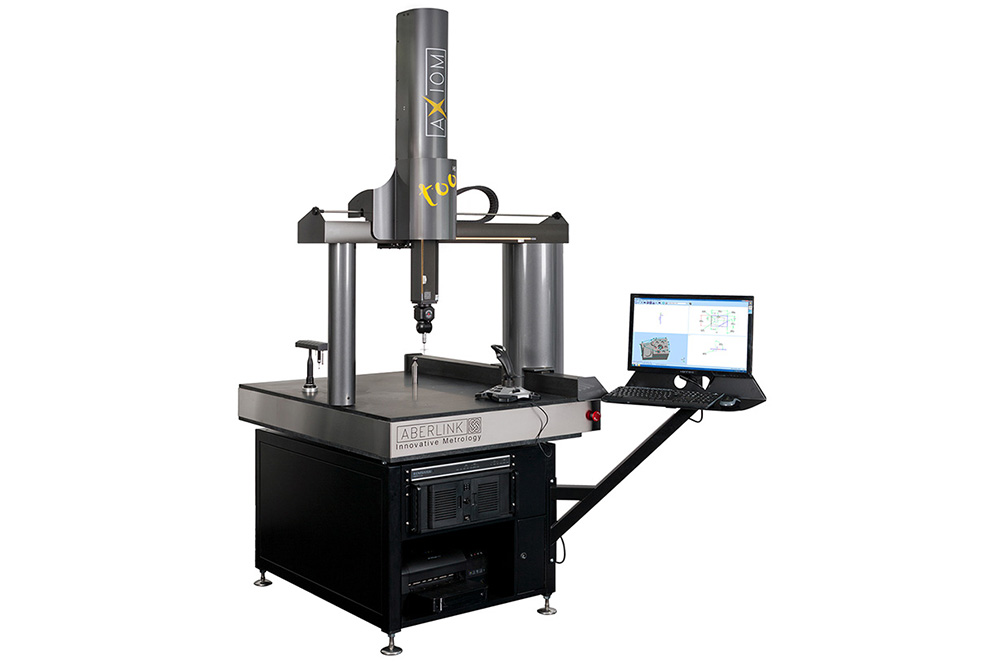

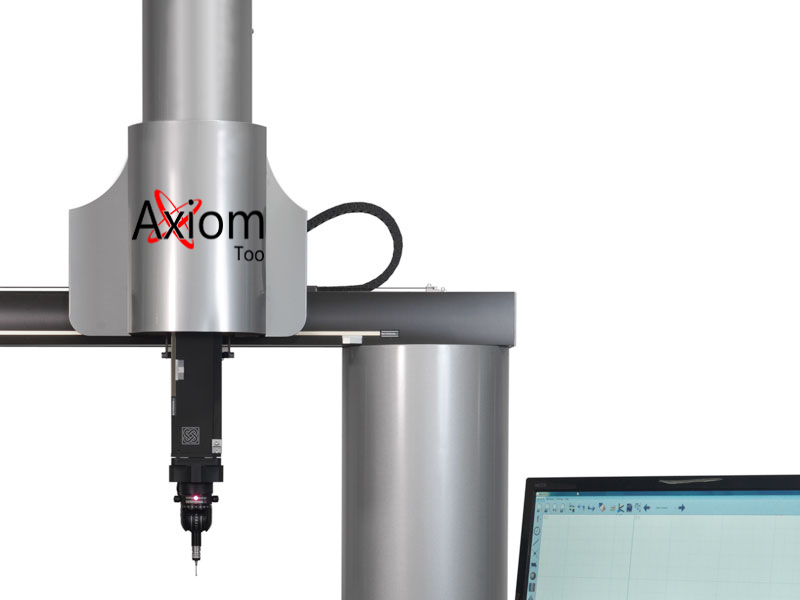

LinkSince 2004 the Axiom too CMM has been providing manufacturing industry with a fast and accurate solution for their measurement problems. Improving on the standard model, the Axiom too HS is both faster and more accurate without compromising the fantastic value for money for which Aberlink CMMs are renowned.

Key features

- Aberlink’s revolutionary easy-to-use measurement software

- Shortest learning curve of any equivalent system – 1 day without prior CMM experience

- Smallest overall footprint of any comparable size CMM

- Choice of Y axis sizes ranging from 600mm to 1500mm

- 0.0001mm linear encoders for superior accuracy

- Zero backlash drive system for quicker acceleration and faster travel

- Suitable for the workshop environment

- Optimised friction free air bearings, all aluminium bridge and granite table

- Free stylus change rack with every motorised probe head upgrade

Eliminate inspection bottlenecks

Related products

Aberlink Fulcrum CMM

Inspect your parts through every step of the manufacturing process. The Fulcrum is a revolutionary…

Aberlink HORIZON 1000 CNC CMM

Drawing upon the tremendous success of the Horizon 800, the Horizon 1000 has a larger…

Aberlink AXIOM Too Manual CMM

An ultra-affordable shop floor CMM for measuring small to medium parts, the Axiom too Manual…

Aberlink AZIMUTH CNC CMM

As CMMs get larger, it is not simply a case of scaling up the design…

Aberlink HORIZON 800 CNC CMM

The Horizon 800 CMM breaks new ground in design and innovation using frictionless linear drives,…

Aberlink AXIOM Too CNC CMM

Fast, accurate and reliable, the Axiom Too CMM comes in four different sizes with Y…

Aberlink EXTOL CNC CMM

Designed for robustness and reliability, the Extol CMM will run around the clock making it…

Trimos C-Line CNC CMM

The New Trimos C-Line is the world’s first truly portable Coordinate Measuring Machine (CMM) and…