File Download

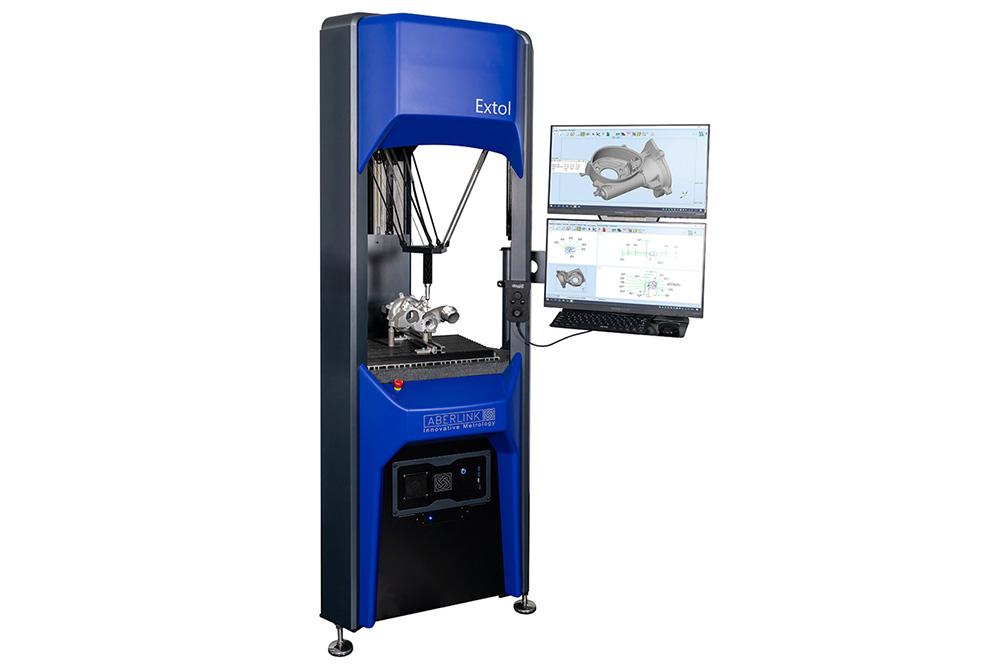

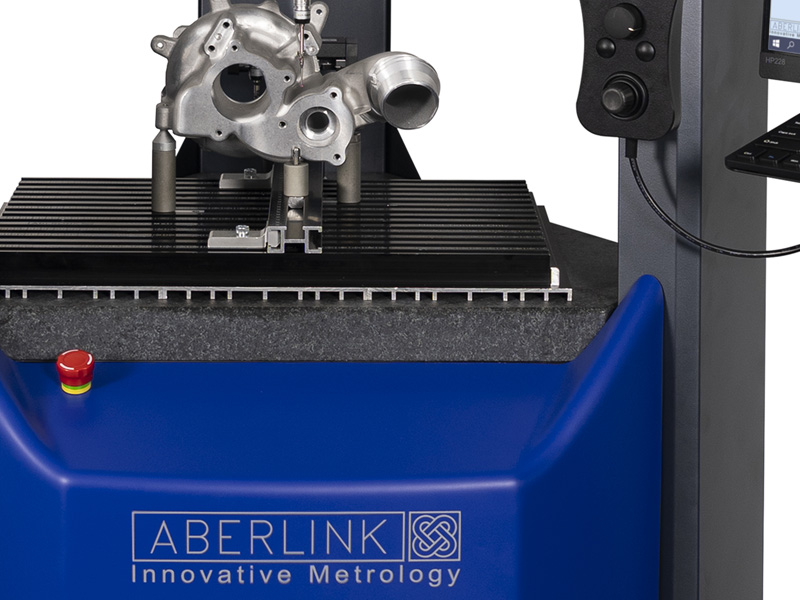

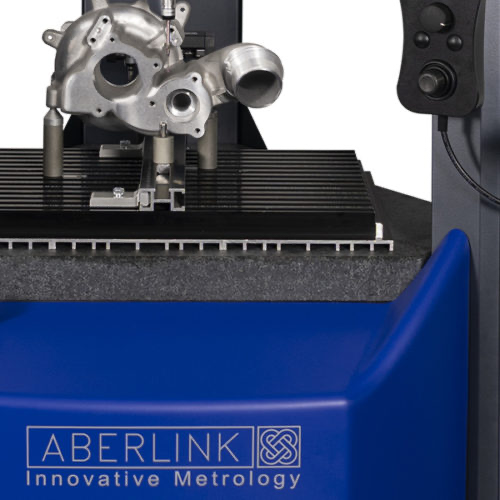

LinkDesigned for robustness and reliability, the Extol CMM will run around the clock making it ideal whether it is positioned next to a machine tool, in a manufacturing cell, or used in a dedicated inspection area.

Five temperature sensors monitoring both the machine and ambient temperature ensure that the Extol is capable operating in uncontrolled environments and reporting measurements as though they had been taken at 20°C. The software will also produce a warning should the temperature be changing at a rate that is not conducive with reasonable metrology practice.

Robust, accurate and reliable, the Extol CMM is the perfect solution to automatically verify part quality for critical components.

Key features

- Fully sealed recirculating cross-roller bearings for dirt immunity

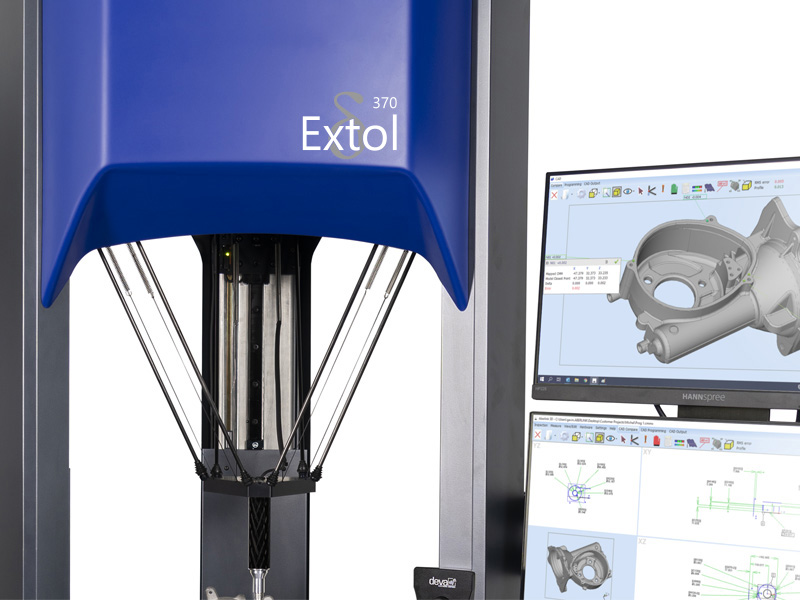

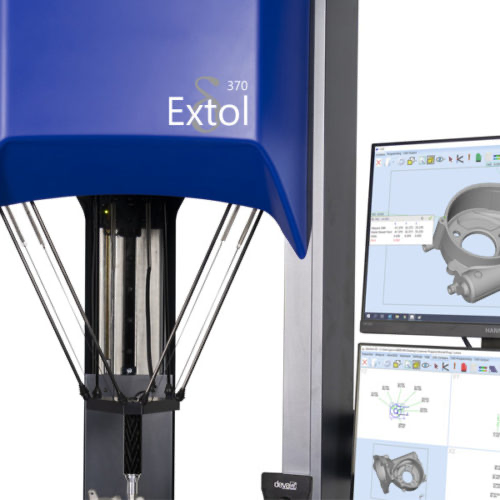

- Swiss-made DC motors and new Deva motion control system provide shop floor reliability

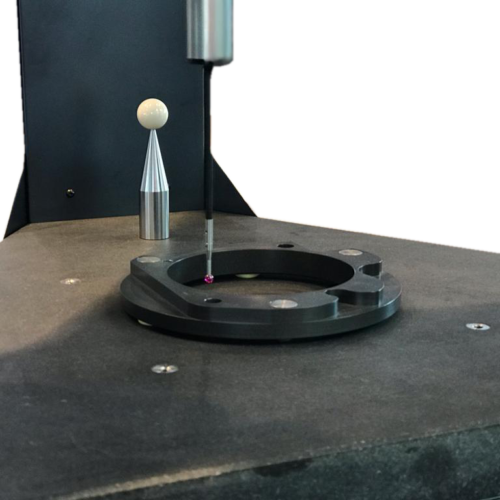

- Super-smooth belt-drives and linear bearings enable long styli to be used without false triggering through vibration

- Automatic tool offset correction and automation options allow integration into fully automated manufacturing cells

- Aberlink’s revolutionary easy-to-use measurement software

- Shortest learning curve of any equivalent system – 1 day without prior CMM experience

- Smallest overall footprint of any comparable size shop floor CMM

- Industrial joystick as standard

CMM accuracy wherever you need it

True to Aberlink’s heritage for innovation, the Extol is the world’s first CMM to utilise a delta mechanism.

Related products

Aberlink Fulcrum CMM

Inspect your parts through every step of the manufacturing process. The Fulcrum is a revolutionary…

Aberlink HORIZON 1000 CNC CMM

Drawing upon the tremendous success of the Horizon 800, the Horizon 1000 has a larger…

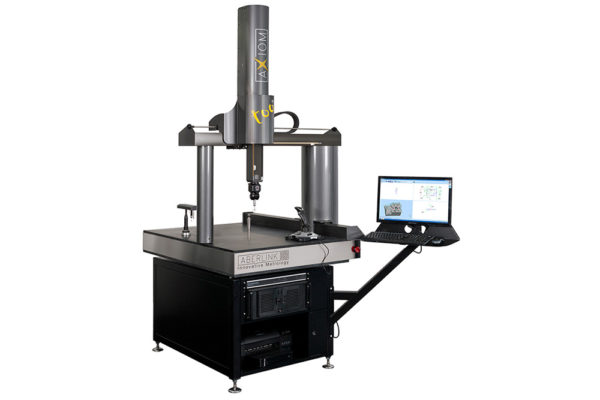

Aberlink AXIOM Too Manual CMM

An ultra-affordable shop floor CMM for measuring small to medium parts, the Axiom too Manual…

Aberlink AZIMUTH CNC CMM

As CMMs get larger, it is not simply a case of scaling up the design…

Aberlink HORIZON 800 CNC CMM

The Horizon 800 CMM breaks new ground in design and innovation using frictionless linear drives,…

Aberlink AXIOM Too HS CMM

Since 2004 the Axiom too CMM has been providing manufacturing industry with a fast and…

Aberlink AXIOM Too CNC CMM

Fast, accurate and reliable, the Axiom Too CMM comes in four different sizes with Y…

Trimos C-Line CNC CMM

The New Trimos C-Line is the world’s first truly portable Coordinate Measuring Machine (CMM) and…