File Download

LinkThe New Trimos C-Line is the world’s first truly portable Coordinate Measuring Machine (CMM) and part of the new Trimos 3D product group along with the recently introduced Trimos Portable Arm. The New C3 & C4 is only 13.5KG so allows you to take the machine right to the parts in the manufacturing process for inspection. Both models are battery operated and available with Bluetooth for full portability.

Manual measurements can be made using the C3 version with the C4 being fully CNC operated.

Ease of use is provided with and intuitive icon-based touch screen mounted on the machine. Optional Aberlink Software is available that will assist in CAD programming and traditional CMM style reporting

Key features

- A working volume of X & Y of 700mm and Z 250mm

- Small footprint and very portable

- High precision measurement using Renishaw TP20 probe

- Ease of use thanks to the Aberlink software

- Fully CNC combined with manual operation

- Designed for workshop operation

- Ethernet communication or wireless (WiFi / Bluetooth)

The world’s first truly portable Coordinate Measuring Machine

Related products

Aberlink Fulcrum CMM

Inspect your parts through every step of the manufacturing process. The Fulcrum is a revolutionary…

Aberlink HORIZON 1000 CNC CMM

Drawing upon the tremendous success of the Horizon 800, the Horizon 1000 has a larger…

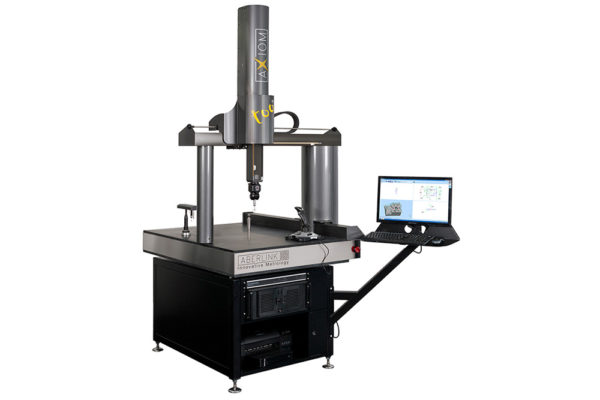

Aberlink AXIOM Too Manual CMM

An ultra-affordable shop floor CMM for measuring small to medium parts, the Axiom too Manual…

Aberlink AZIMUTH CNC CMM

As CMMs get larger, it is not simply a case of scaling up the design…

Aberlink HORIZON 800 CNC CMM

The Horizon 800 CMM breaks new ground in design and innovation using frictionless linear drives,…

Aberlink AXIOM Too HS CMM

Since 2004 the Axiom too CMM has been providing manufacturing industry with a fast and…

Aberlink AXIOM Too CNC CMM

Fast, accurate and reliable, the Axiom Too CMM comes in four different sizes with Y…

Aberlink EXTOL CNC CMM

Designed for robustness and reliability, the Extol CMM will run around the clock making it…